CMP (Chemical Mechanical Polishing) is a process that polishes and planarizes the surface layer of the material with chemical and mechanical method by injecting polishing slurry and having the polishing pad and the material surface rub against each other.

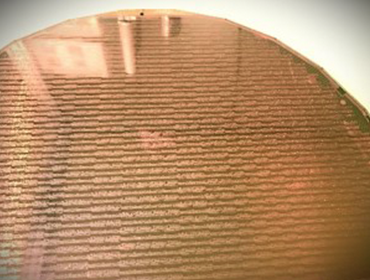

It is an essential core process in the fabrication and lamination processes for MEMS structures. Our MEMS CMP (Chemical Mechanical Polishing) process capability for various materials such as Silicon Wafer, Silicon Nitride (Si3N4), SiC, Sapphire, Quartz, Glass and Polyimide as well as various specifications are the best in Korea.

| 2" | 4" | 6" | 8" | 12" |

|---|---|---|---|---|

| 50um /±1um | 50um /±1um | 50um /±1um | 90um /±1um | 100um /±2um |